Increase your

Productivity & Efficiency with the OEE.Box

Maximize your machine utilization and minimize downtime!

To The Point!

The OEE.Box is a powerful tool for the digital acquisition of your machine data. With our intelligent sensors and user-friendly software, you have real-time monitoring of your production performance anytime, anywhere.

If you still record your machine efficiency and your operating data manually, the OEE.Box will inspire you!

4 Steps to Digitization!

1. Connect the OEE.Box to your Machines

The OEE.Box consists of the AndinoX1, a traffic light and a barcode scanner. The Andino X1 is a small industrial PC that is connected to a clock output of your machine with a wire. This can be a signal from the machine control or a light barrier.

2. Choose the Order and/or Employee using a Barcode Scanner.

The current order is scanned in using a barcode scanner so that the OEE.Box can assign the process key figures to the respective order. In addition, the corresponding employee can also be booked in to the corresponding order via barcode.

3. The OEE.Box records your Process Data, the Traffic Light signals the Status of the Job.

In the background, the OEE.Box now records the cycles for the running order of the machine. If the signal fails to appear, the OEE.Box registers a standstill and records it with the order, the article and the reaction time from the occurrence of the error to the posting of the error in the system. The traffic light lights up red and immediately visualizes the standstill to the employees.

4. Access your Data from Anywhere.

The OEE.Box is an open system in which various interfaces (database, Excel, JSON and web view) are integrated. Thus, the collected data can be clearly evaluated and easily processed. You can access the data from anywhere via web view.

A data collection system that doesn't turn your IT on its head.

Simple Installation

Prebuilt reports

Optionally with production line monitors

Say Goodbye To...

- Messy paperwork at the workplace

- Time-delayed production data

- Manual compilation of data

- Non-transparent machine data

- Time-consuming analyses with incorrect data records

- Data chaos in production

We are solution-oriented!

That is why we offer you...

- After installation we guarantee you your first own data output within 14 days!

- We do NOT turn our solution into a complex IT project.

- Complete solution out of the box, no need for your own hardware or software!

Your benefits for...

-

Increased transparency

Our OEE.Box enables the monitoring and control of processes in real time. This gives your production staff a better overview of production and allows them to react more quickly to deviations. -

Improved efficiency

Our OEE.Box documents the process automatically. This increases productivity and reduces costs. -

Reduces errors

Our OEE.Box enables trends and deviations to be identified at an early stage. In this way, errors in production can be detected and corrected at an early stage. -

Piecework wage

Our solution enables your employees to calculate their piecework wages accurately and transparently. Don't argue with your employees, show them the data directly, visually and for the better The best way to motivate yourself is to look at your hall monitor. -

Training needs

Continuous data collection enables you to identify performance drops or error rates in order to develop targeted training measures for your employees. Or to assess the quality of the induction of new employees.

-

Real-time monitoring

Our OEE.Box allows you to permanently monitor each scrap part at the time it is created so that you have everything in view. -

Deficiency emergence data in context

Through the constant digital collection of production data, you can identify trends, patterns and deviations more quickly and take countermeasures. -

Reliable order times

With complete, real-time monitoring, you can calculate the real ACTUAL throughput times for orders. Which offers you better planning security and customer satisfaction. -

Less manipulative

When recording quantities, running meters and downtimes, digital recording is more accurate and less susceptible to manipulation. -

Data security

Our OEE.Box is equipped with the latest security mechanisms to protect your production data from unauthorized access and data loss. You can be sure that your data is saved and protected even during power failures.

-

Increase in lifespan

of machines and systems through regular, needs-based maintenance. Because you can see the quantities actually produced in the context of real ACTUAL data on disruptions. -

Increase productivity

Our OEE.Box enables you to automate processes and use resources more efficiently, leading to a significant increase in productivity. -

Spare parts management

With the data in the context of quantity and fault data, you can calculate better forecasts for wearing parts and thus act in advance and order spare parts. -

Ideal time for maintenance

By constantly evaluating the machine data, you can plan the optimal maintenance time for machines and systems within the production processes. So that your production does not come to a standstill and you significantly reduce unplanned downtime. - Better communication Increase collaboration and communication by being able to share data in real-time and make related decisions faster

-

Increase productivity

Our OEE.Box enables you to automate processes and use resources more efficiently, leading to a significant increase in productivity. -

Increase in quality

Our OEE.Box allows you to closely monitor and control processes, resulting in an increase in the quality of the goods produced. -

Cost Savings

Our OEE.Box enable you to better manage resources and streamline operations, which can lead to significant cost savings. -

Transparency

Our OEE.Boxes offer you a comprehensive overview of your production processes, which leads to more transparency and better decision-making. You always have the option of calling up and analyzing production data in order to identify weak points and optimize processes. -

Time savings

Receive evaluations and reports within seconds, as there is no time-consuming manual compilation of complex data.

Features for every purpose

The OEE.Box is versatile and expandable. Especially important for our customers are these:

Determining the degree of utilization and OEE

Visual signals in case of standstills and malfunctions

Interfaces to Excel, JSON and more

Web interface for access from anywhere and at any time

User-friendly acquisition of operational and machine data

Real-time analyses of downtimes, cycle losses, order times, piece counts, ...

Determination of production data for the assessment of efficiency

Capacity analyses

Why go with Us?

Fast & Dynamic

As a manufacturer of IT and hardware, we can guarantee fast and secure implementation within a few days. We even network antique machines with our digital solution, so you get a real overall data picture of your production.

Strong & Sturdy

Hardware and IT come directly from a single source. We offer thoughtful design with high-quality components. The OEE.Box is "Made in Germany".

Intuitive & Simple

The OEE.Box has a first-class intuitive control so that your employees are not burdened with learning technical processes.

Efficient & Effective

Every minute of unused machine time costs money. The OEE.Box is the solution for using your machines more intelligently and increasing the productivity of your production.

Industrial sectors

In the plastics processing industry, the OEE.Box is used, among other things, to monitor the effectiveness of injection molding and extrusion machines.

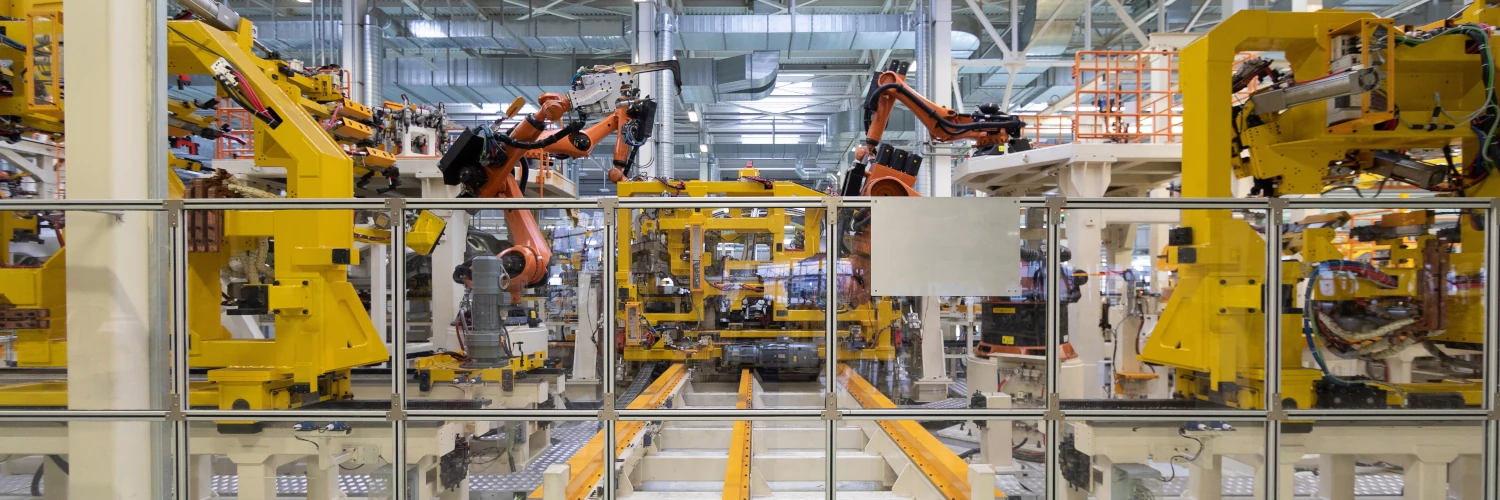

In the automotive industry, the OEE.Box can be used to monitor the effectiveness of production lines, assembly and painting lines.

In the food industry, the OEE.Box is used to monitor and improve the effectiveness of production lines, such as filling lines, packaging machines and conveyors.

In the woodworking industry, Clear Systems' OEE.Box can be used to monitor the effectiveness of saws, planers and sanders.

Among other things, companies operating in the metalworking industry use the OEE.Box to monitor the effectiveness of CNC machines, presses and lathes.

In foundries, the OEE.Box from Clear Systems can be used to monitor the effectiveness of casting machines, decoring and deburring machines as well as melting furnaces and dosing systems.

Your possibilities...

1. Test our OEE.Box

So that you don't buy a pig in a poke! Due to the quick and simple implementation, the test phase is suitable for anyone who is still undecided. You and your employees can then evaluate whether the OEE.Box is just right for you and your company.

2. Rent our OEE.Box

So that you remain economically flexible! With our rental model, you can start without any obligation and without having to invest in advance. Scale risk-free and just rent.

3. Buy our OEE.Box

Invest in your future and stay independent! Purchasing gives you full control and you may be eligible for funding opportunities. It is best to get advice on this in advance.

We offer complete price transparency!

So that you and your employees are satisfied!

See our conditions for the different models.

Check your funding options

The OEE.Box enables the digitization of your production processes, which is why it may be eligible for many companies. The best thing to do now is to get advice from your local chamber of commerce.

Current relevant funding programs:

- Digitalbonus Bayern(for companies in Bavaria)

- Digital Jetzt(for companies in Germany)

- Other similar programs are available in many other regions of Europe!

Contact IHK Bayreuth

Mr. Buus - digitization/IT security

Phone: +49 921 886470

If your company is located in Germany, you are also welcome to use the German federal funding database inform:

www.foerderdatenbank.deContact Us

Request your free quote:

info@clearsystems.de

Phone: +49 9197 2353235